Calcined Kaolin

- Product Name:Calcined Clay

- Chemical Formula:Al2Si2O5(OH)4

- Temperature:500°C to 1200°C

- Characteristics:Improved Brightness

and Opacity

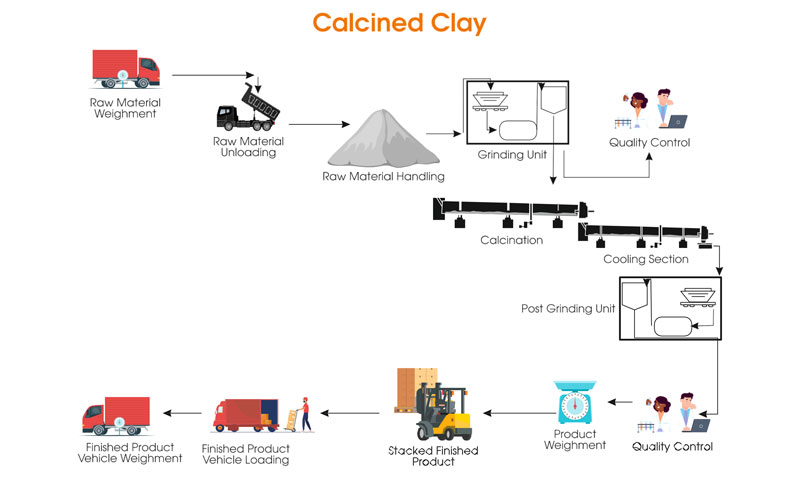

Calcined Clay

Calcined kaolin refers to a process in which kaolin clay, a type of clay mineral, is heated to high temperatures to remove water and other volatile compounds, transforming it into a different form. Kaolin clay is a naturally occurring mineral with the chemical composition Al2Si2O5(OH)4, and it is commonly found in the earth's crust. The calcination process involves firing the kaolin clay at temperatures typically ranging from 500 to 1200 degrees Celsius (932 to 2192 degrees Fahrenheit).

During calcination, the following changes occur:

- Dehydration: The kaolin clay loses its water molecules, making it less plastic and more friable.

- Decomposition of Hydrates: The removal of water also leads to the decomposition of hydrates and other volatile compounds present in the clay.

- Crystal Structure Changes: The mineral undergoes changes in its crystal structure, resulting in alterations to its physical and chemical properties.

Here are some key features and applications of calcined kaolin:

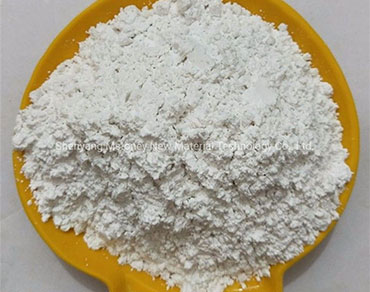

The calcined kaolin produced through this process is characterized by improved brightness, opacity, and whiteness compared to the raw kaolin. It also exhibits altered physical properties that make it suitable for various industrial applications, including:

- Paint and Coatings: Calcined kaolin is commonly used as an extender in paint formulations to improve opacity, whiteness, and texture.

- Paper Industry: It is used as a filler in paper production to enhance brightness, smoothness, and printability.

- Plastics and Rubber: Calcined kaolin is employed as a reinforcing agent in plastics and rubber industries to improve strength, abrasion resistance, and other properties.

- Ceramics: In ceramics, calcined kaolin is used to improve the fired color, texture, and strength of the final products.

- Construction Industry:It finds applications in the construction industry as a functional filler in concrete, mortar, and other building materials.

Calcined kaolin is valued for its versatility and its ability to enhance the performance of various products across different industries. The specific properties of calcined kaolin can vary depending on factors such as the temperature and duration of the calcination process.

Classification Of Calcined Kaolin

Asterfil

Astercot

Astertex

Asterfine

Astergloss

Needs Help? Let’s Get in Touch